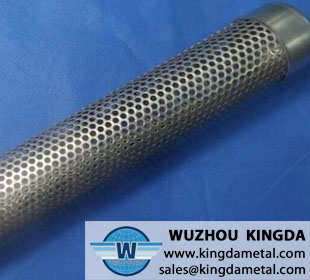

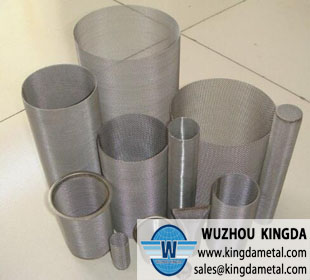

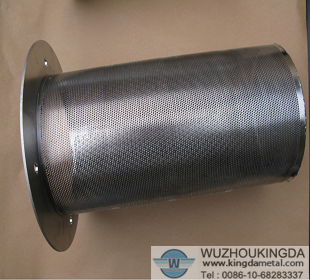

Punching filter tube

Punching filter tube

- Category:Filter Screen

- Material:low carbon steel, stainless steel and so on

- Properties:punched to mesh

- Application:

or

We highly appreciate your feedback. TEL: 0086-10-68287775

E-mail: sales@kingdametal.com

E-mail: sales@kingdametal.com

- Mesh Description

- Contact Form

- Recommend Products

Punching filter tube

1. Materials: low-carbon steel, stainless steel plate, aluminum, copper; stainless steel mesh 304 304L 316 316L has better properties than the other materials.

2. Punching filter tube characteristics:

2.1 Good Gas Permeability

2.2 Good Resistance to Corrosion, Heat, and Abrasion

2.3 Homogeneous Pore Distribution, high filtration and convenient to operate

2.4 High Flow Quantity per Unit Area

2.5 Good Chemical Resistance

2.6 stainless steel mesh filters have long service life.

3. Shape of Punching filter tube: round, rectangle, oval, crescent and semicircle and so on.

4. Punching filter tube applications:

It is widely used in the absorption, evaporation and filtration process of chemical fiber, rubber, pharmacy, wine-making, beverage and also can be used in the area of the Mechanical filtration industry.

5. Key Information for ordering Punching filter tube?

Tube Design

Diameter (O.D. and/or I.D)

Length

Gauge or Material Thickness

Perforation Pattern

Material Type: Tin, Stainless Steel, Galvanized, Brass, Aluminum and Cold Rolled Steel

End Margin Requirements

Quantity (Annual Volume & Release Quantity)

Packaging Requirements

Any Certifications, Warrants, or PPAP Requirements

Delivery Requirements

Other Critical Characteristics or Information

6. Reference specification of Punching filter tube:

1. Materials: low-carbon steel, stainless steel plate, aluminum, copper; stainless steel mesh 304 304L 316 316L has better properties than the other materials.

2. Punching filter tube characteristics:

2.1 Good Gas Permeability

2.2 Good Resistance to Corrosion, Heat, and Abrasion

2.3 Homogeneous Pore Distribution, high filtration and convenient to operate

2.4 High Flow Quantity per Unit Area

2.5 Good Chemical Resistance

2.6 stainless steel mesh filters have long service life.

3. Shape of Punching filter tube: round, rectangle, oval, crescent and semicircle and so on.

4. Punching filter tube applications:

It is widely used in the absorption, evaporation and filtration process of chemical fiber, rubber, pharmacy, wine-making, beverage and also can be used in the area of the Mechanical filtration industry.

5. Key Information for ordering Punching filter tube?

Tube Design

Diameter (O.D. and/or I.D)

Length

Gauge or Material Thickness

Perforation Pattern

Material Type: Tin, Stainless Steel, Galvanized, Brass, Aluminum and Cold Rolled Steel

End Margin Requirements

Quantity (Annual Volume & Release Quantity)

Packaging Requirements

Any Certifications, Warrants, or PPAP Requirements

Delivery Requirements

Other Critical Characteristics or Information

6. Reference specification of Punching filter tube:

|

mesh/inch |

wire gauge SWG |

aperture MM |

|

40*40 |

36 |

0.44 |

|

50*50 |

38 |

0.36 |

|

60*60 |

40 |

0.30 |

|

80*80 |

42 |

0.21 |

|

100*100 |

44 |

0.17 |

|

200*200 |

47 |

0.077 |

|

300*300 |

49 |

0.052 |

|

400*400 |

50 |

0.0358 |